2025 Tech Trends in Automation Valves: How to Choose the Best Solutions for Your Industry

As industries increasingly embrace digital transformation, the adoption of Automation Valves is projected to surge significantly by 2025. According to a recent report by MarketsandMarkets, the global automation valves market is expected to reach USD 5.64 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2% from 2020. This growth is driven by the rising demand for efficient process automation in sectors such as oil and gas, chemicals, and water treatment. With advancements in IoT and AI technologies, choosing the right Automation Valves has never been more critical. Industries must consider factors such as compatibility, reliability, and integration capabilities to ensure optimal performance and sustainability. In this blog, we will explore the key tech trends shaping the future of Automation Valves and provide insights on how to select the best solutions tailored to your specific industry needs.

Understanding the Role of Automation Valves in Modern Industries

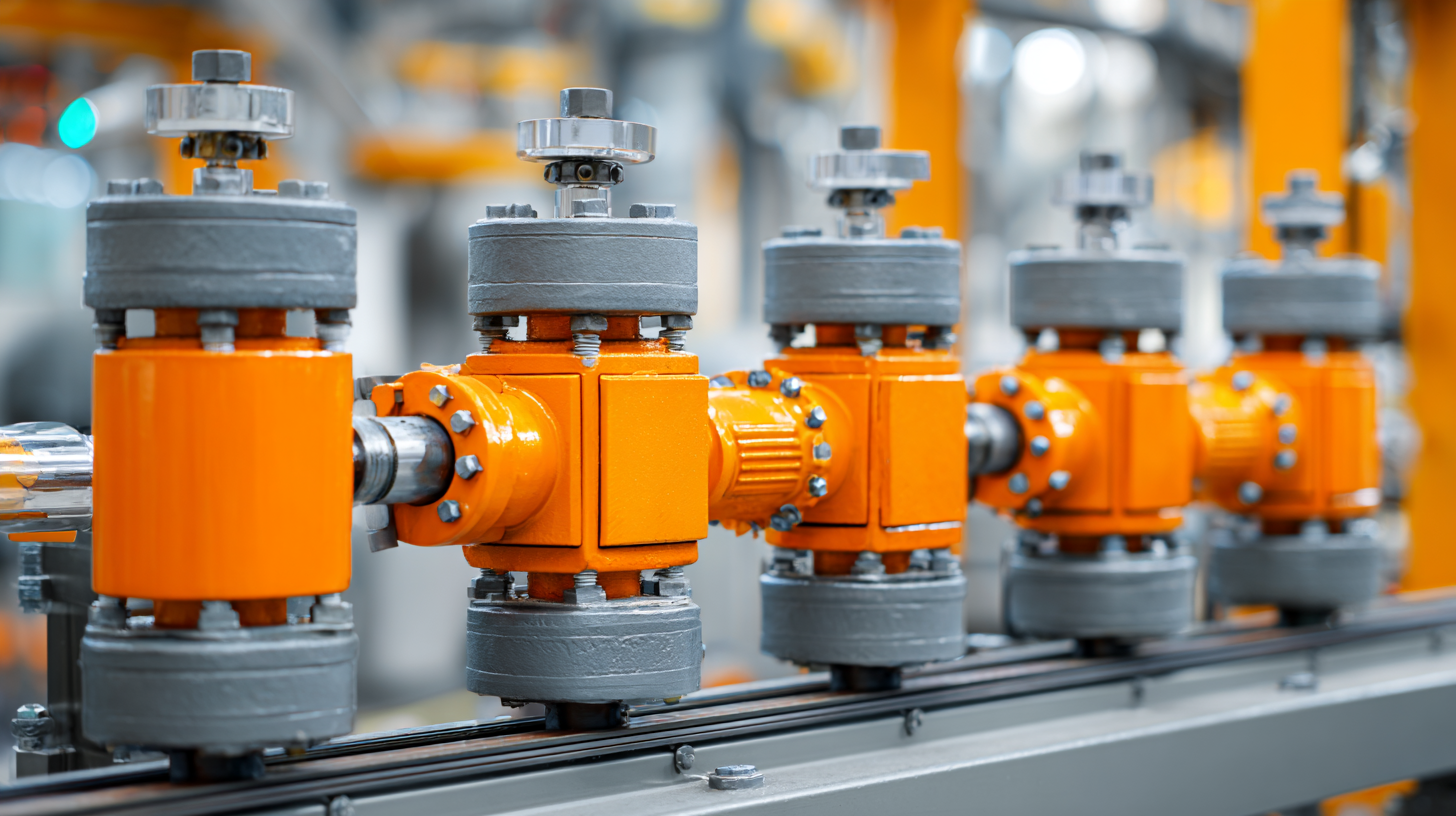

Automation valves play a pivotal role in streamlining processes across various modern industries. These devices are designed to control fluid flow and pressure automatically, enhancing operational efficiency and safety. From oil and gas to pharmaceuticals and food processing, the integration of automation valves allows for precise control, reducing the risk of human error and optimizing resource management. As industries continue to evolve, these valves are becoming increasingly sophisticated, equipped with advanced sensors and control systems that enable real-time monitoring and adjustments.

Choosing the best automation valve solutions for your specific industry requires a thorough understanding of your operational needs. Factors such as fluid characteristics, pressure requirements, and environmental conditions play crucial roles in the selection process. Additionally, compatibility with existing systems and the potential for future scalability should be considered. As technology advances, manufacturers are offering valves with enhanced features such as self-diagnostics and predictive maintenance capabilities, which can further contribute to minimizing downtime and maximizing productivity.

2025 Tech Trends in Automation Valves: How to Choose the Best Solutions for Your Industry

| Industry | Common Applications | Key Features of Automation Valves | Trends for 2025 |

|---|---|---|---|

| Oil and Gas | Flow regulation, safety shutoff | Remote monitoring, real-time data | Increased IoT integration |

| Water Treatment | Chemical dosing, flow control | Smart automation, predictive maintenance | Sustainability-driven automation |

| Food & Beverage | Processing, packaging | Hygienic designs, traceability | Enhanced safety features |

| Pharmaceuticals | Drug production, sterilization | Precision control, compliance monitoring | Increased regulatory compliance |

| HVAC Systems | Temperature regulation, airflow control | Energy efficiency, smart controls | AI-driven climate management |

Key Features to Consider When Choosing Automation Valves

When selecting automation valves for your industry, several key features should guide your decision-making process. Firstly, assess the valve's compatibility with the fluids you will be handling. The material used in valve construction greatly affects its performance and lifespan, especially in corrosive or high-temperature environments. For instance, stainless steel may be more suitable for harsh conditions, while plastic valves might suffice for less demanding applications.

Another crucial factor is the valve’s actuation method. Depending on your operational needs, you might prefer electric, pneumatic, or hydraulic actuation. Electric actuators are known for their precision and easy integration with control systems, while pneumatic options offer rapid response times and are often more cost-effective for larger applications.

Additionally, consider the ease of maintenance and the availability of diagnostic features. Valves with built-in diagnostics can provide valuable insights into performance and potential issues, helping you maintain operational efficiency and minimize downtime.

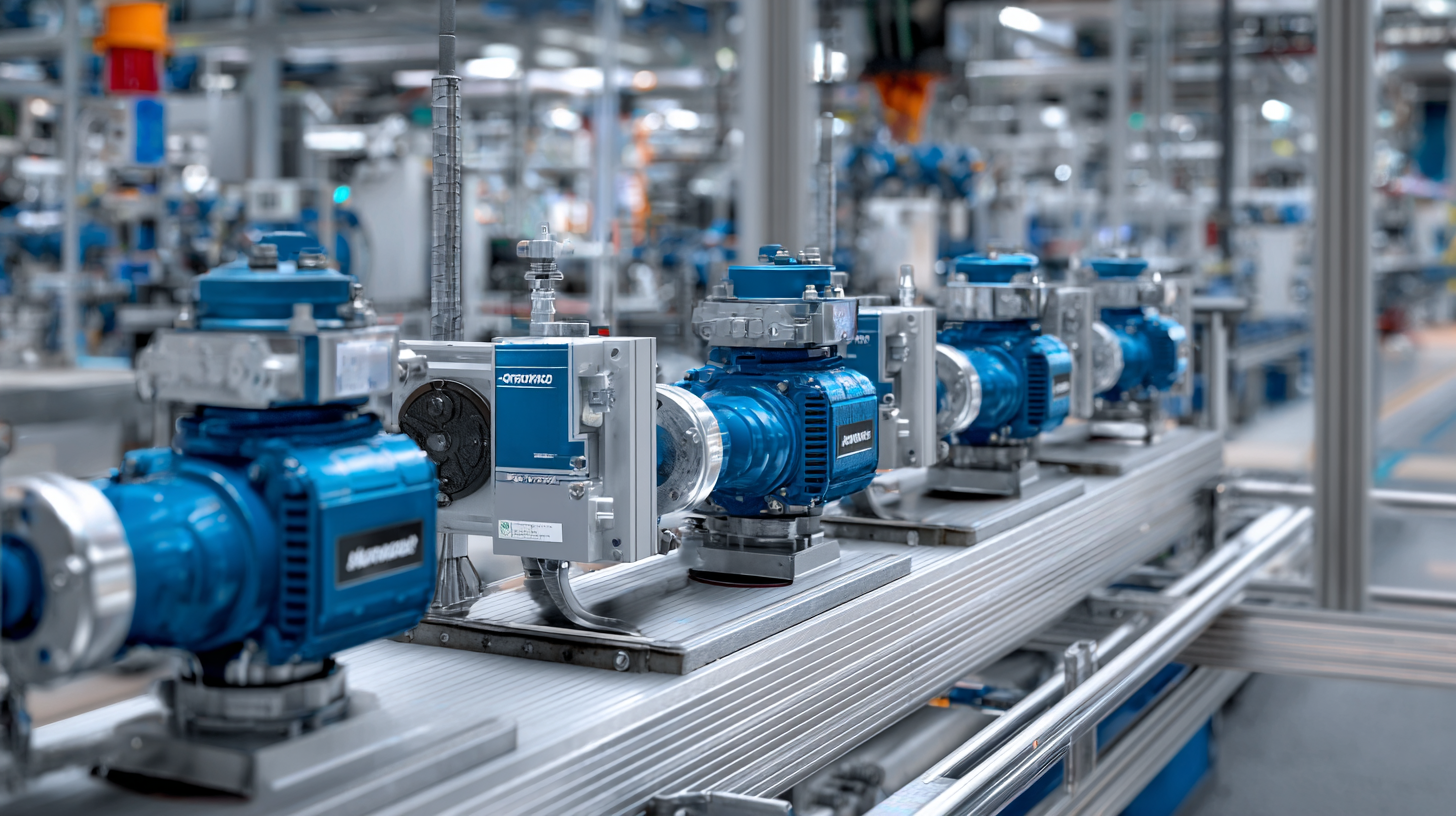

Comparative Analysis of Different Automation Valve Types

In 2025, the automation valve market is poised for significant growth, driven by advancements in smart technologies and increasing demand across various industries. A comparative analysis of different automation valve types reveals critical differences in performance, functionality, and application that can greatly influence decision-making. According to a recent report by MarketsandMarkets, the automation valve market is expected to reach USD 8.6 billion by 2028, growing at a CAGR of 6.5%. This highlights the need for industries to adopt the most efficient solutions available.

When choosing automation valves, organizations must consider factors such as valve type, actuation method, and operational requirements. For instance, globe valves, known for their precise flow control, are ideal for applications requiring throttling. Conversely, ball valves provide quick shut-off and are often preferred for on/off control in high-flow systems. Additionally, electric actuators are increasingly becoming favorable due to their reliability and enhanced control capabilities, as evidenced by a 2021 study by Frost & Sullivan indicating a 28% growth in electric actuator adoption over the previous five years. Ultimately, selecting the right type of automation valve is crucial for optimizing operational efficiency and ensuring compliance with industry standards.

Future-Proofing Your Operations: Trends in Automation Valve Technology

As industries aim to future-proof their operations, the trends in automation valve technology present exciting opportunities for optimization and efficiency. With the global industrial valve market expected to grow from USD 84.97 billion in 2025 to USD 128.22 billion by 2035, it's crucial for companies to embrace innovative solutions that can enhance fluid control systems. Key technologies driving this evolution include mobile robots and artificial intelligence, which facilitate smoother operations and increase reliability.

In 2023, five key enablers for autonomous operations, such as advanced open-process automation and 5G communications, are emerging as critical components for businesses looking to stay ahead. Adoption of solenoid valves, which are becoming increasingly essential for industrial automation, further boosts process efficiency and performance. As the industry anticipates a compound annual growth rate (CAGR) of 4.2% through 2035, organizations must strategically choose the best automation valve solutions to secure their competitive edge and drive long-term growth.

Cost vs. Performance: Finding the Right Balance for Your Industry Needs

When evaluating automation valves for your industry, understanding the delicate balance between cost and performance is crucial. The myriad of choices available may seem overwhelming, yet it's essential to align these solutions with your specific operational requirements. As industries evolve, the performance of automation valves can significantly influence productivity, much like how attention to employee health boosts workplace productivity, as seen in recent trends. Prioritizing high-performance solutions often leads to longer-term savings by reducing downtime and maintenance costs, making the initial investment worthwhile.

In 2025, sectors such as chemicals and banking are emphasizing innovation and efficiency while adapting to changing economic landscapes. This trend indicates that selecting automation valves shouldn't solely focus on upfront costs; performance metrics, such as reliability and scalability, are equally important. Organizations must consider how these valves can integrate with advancements in AI and data centers, enhancing their operational frameworks. Striking the right balance ensures that investments not only promote immediate operational advancement but also contribute to sustainable growth in an increasingly competitive environment.

2025 Tech Trends in Automation Valves: Cost vs. Performance Analysis

This chart illustrates the trade-off between cost and performance for various automation valve technologies in 2025, helping industries to make informed decisions based on their specific needs.