Unlocking Excellence: Comprehensive Technical Specifications for the Best Full Port Ball Valve

In the ever-evolving landscape of industrial applications, the importance of selecting the right components cannot be overstated. Among these, the Full Port Ball Valve stands out due to its optimized flow characteristics, making it an essential choice for processes that demand efficiency and reliability. According to a recent report by MarketsandMarkets, the global ball valve market is projected to reach $5.24 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.2%. This growth is driven by increasing demand across various sectors, including oil and gas, water and wastewater treatment, and power generation. As industries seek to enhance operational performance, understanding the technical specifications and alternatives available for Full Port Ball Valves becomes crucial for ensuring excellence in application and overall system integrity. This blog will delve into the nuances of Full Port Ball Valves and explore viable alternatives to help you make informed decisions for your specific needs.

Understanding Full Port Ball Valves: Key Features and Benefits

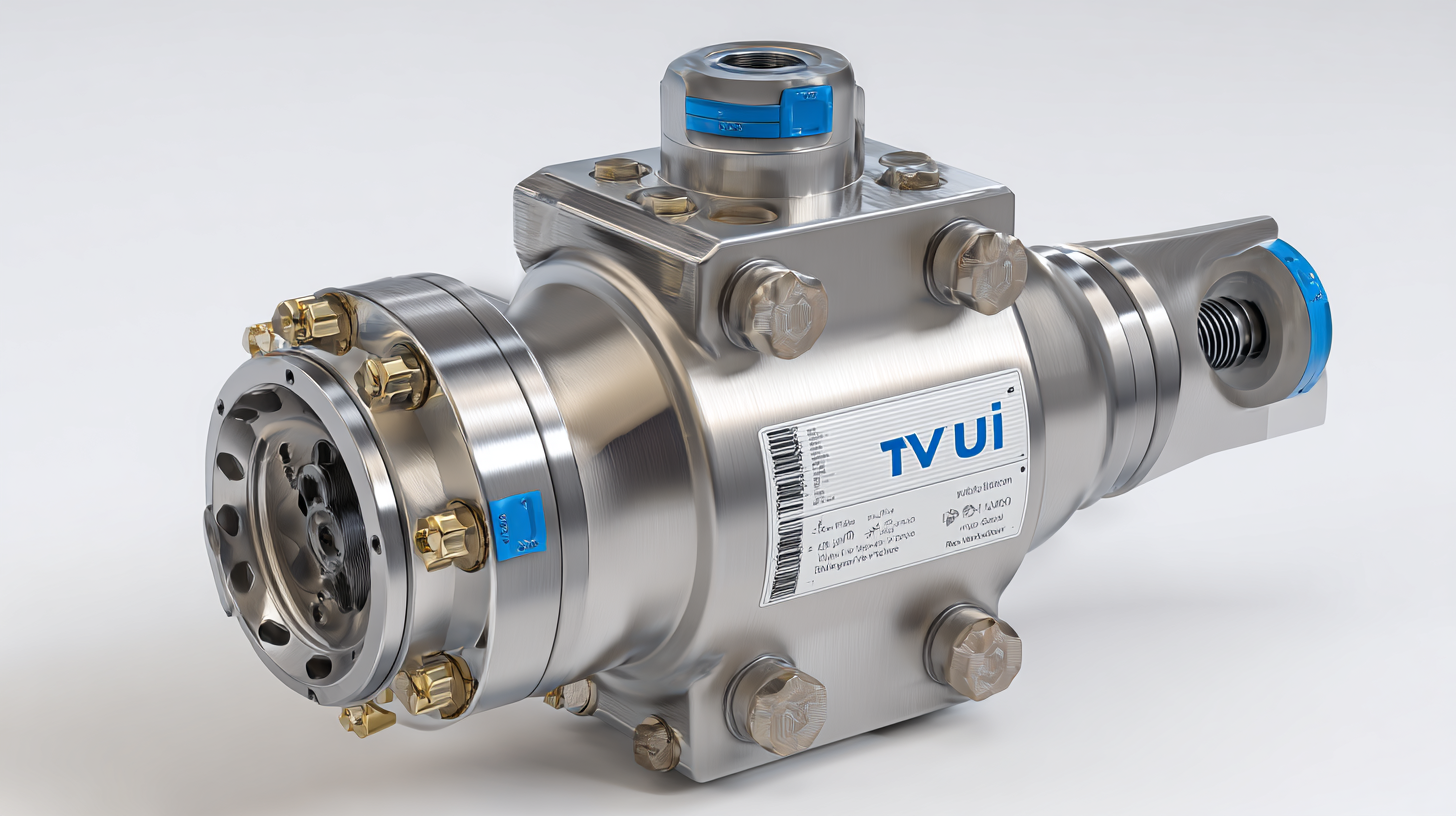

Full port ball valves are designed with a wide inner diameter that allows for unrestricted flow, making them a preferred choice in many industrial applications. This feature significantly reduces pressure drop and turbulence, enabling efficient fluid transfer. Additionally, the full port design minimizes the accumulation of debris within the valve, contributing to a longer lifespan and reliability. This is particularly advantageous in systems where clean flow is crucial.

Another key benefit of full port ball valves is their ability to provide a tight seal, which prevents leaks under high pressure conditions. The ball within the valve creates a flat surface when in the open position, allowing for maximum flow. Moreover, the ease of operation—typically a quarter-turn motion—ensures quick response times in critical situations.

Whether in oil and gas, water treatment, or HVAC systems, understanding these key features can help engineers and purchasing managers make informed decisions that enhance system performance and safety.

Expert Insights: Why Sourcing from Top Chinese Factories Matters

Sourcing full port ball valves from top Chinese factories can significantly enhance the quality and performance of your projects. These manufacturers often utilize state-of-the-art technology and rigorous quality control processes to ensure their products meet international standards. By partnering with reliable suppliers, companies can gain access to advanced engineering capabilities and innovative designs that optimize the operational efficiency of ball valves, leading to reduced maintenance costs and improved system performance.

Moreover, establishing relationships with reputable Chinese manufacturers opens the door to competitive pricing without compromising on quality. The scalability offered by these factories allows businesses to meet varying demands efficiently. Additionally, their commitment to customer service and support can greatly facilitate smoother communication and quicker resolutions to any issues that may arise. Choosing the right supplier not only impacts the immediate quality of the product but also plays a crucial role in the long-term success and reliability of your entire system.

Quality Assurance: The Role of Technical Specifications in Valve Performance

Technical specifications play a critical role in ensuring the performance and reliability of full port ball valves. These specifications encompass various aspects, such as material selection, valve dimensions, pressure ratings, and operational temperature ranges. By adhering to stringent technical standards, manufacturers can guarantee that their valves will perform optimally under specific conditions, preventing unexpected failures and leaks that could compromise system integrity.

Moreover, understanding and applying these technical specifications allows engineers and designers to make informed decisions when selecting components for their projects. This knowledge is key to achieving seamless interoperability within complex fluid systems. Quality assurance protocols that leverage detailed specifications ensure that each valve not only meets performance expectations but also complies with relevant industry regulations. As a result, investing in high-quality technical specifications ultimately enhances valve durability, improves maintenance procedures, and contributes to overall operational efficiency.

Global Trust: Building Reliable Partnerships through Excellence in Manufacturing

In today's competitive industrial landscape, establishing trustworthy partnerships is crucial for success. The manufacturing of full port ball valves exemplifies this principle, where excellence in production processes directly correlates with reliability and performance. Companies that prioritize quality control and adhere to rigorous technical specifications not only enhance their product offerings but also forge lasting relationships with their suppliers and clients. This commitment to excellence becomes the foundation of mutual trust, fostering collaboration that can withstand the test of time.

Moreover, by focusing on continuous improvement and innovation in manufacturing practices, businesses can elevate their standards and set themselves apart in the marketplace. Investing in state-of-the-art technology and skilled workforce ensures that every valve produced meets stringent quality benchmarks. This dedication not only results in superior products but also builds a reputation for reliability in the eyes of partners and customers alike. As companies embrace this holistic approach, they not only unlock operational excellence but also create a solid network of partnerships rooted in shared values and commitment to superior manufacturing.

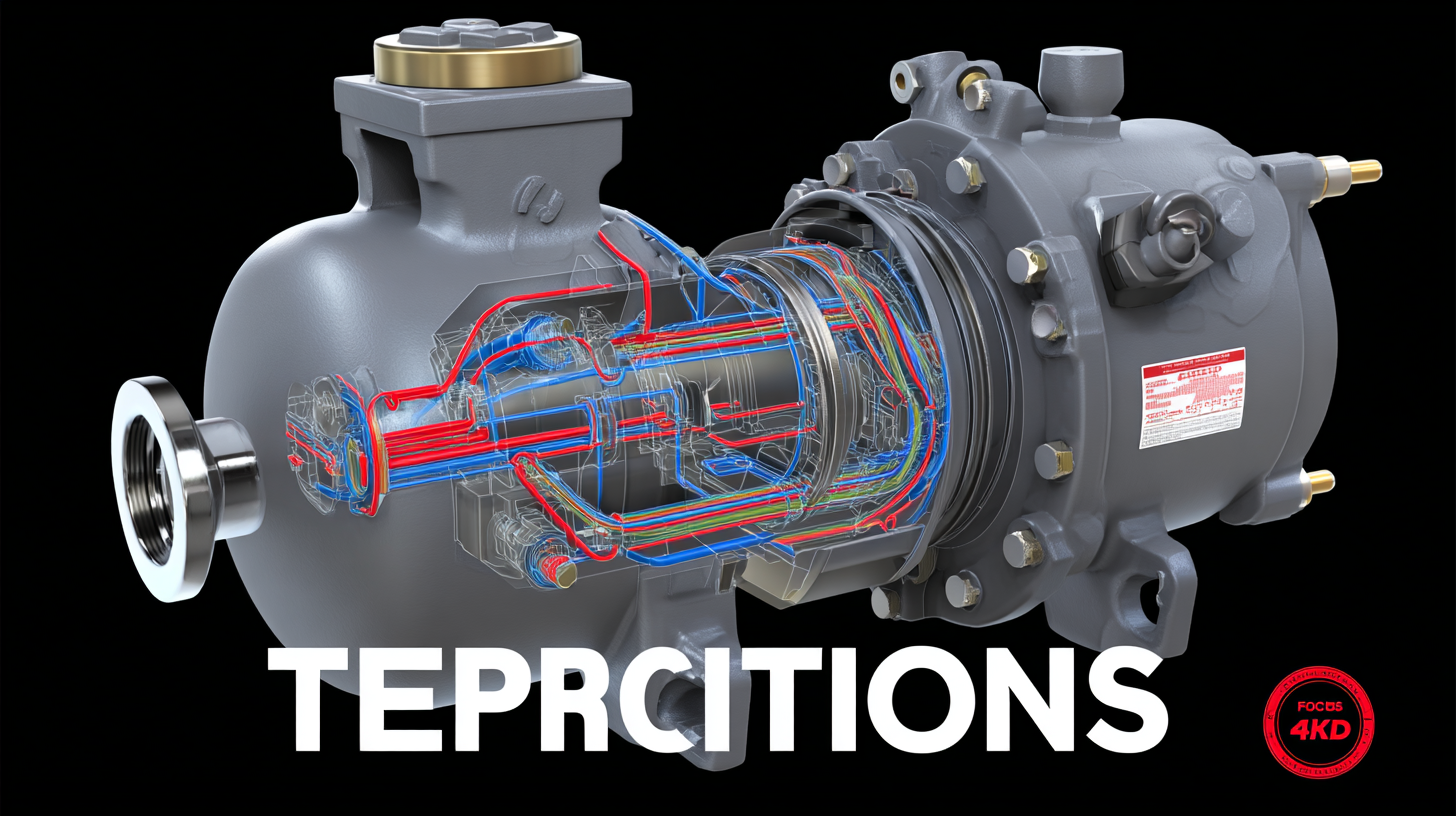

Applications and Innovations: The Future of Full Port Ball Valve Technology

The future of full port ball valve technology is set to revolutionize various industries through its innovative applications and enhanced performance. Recent advancements in precision control valves and modern pumping systems have significantly optimized fluid management in power generation facilities. According to industry reports, these innovations have led to a remarkable improvement in pump efficiency, with some systems achieving up to a 30% reduction in energy consumption. This level of efficiency not only supports sustainable practices but also reduces operational costs, making full port ball valves more appealing in high-stakes environments.

Moreover, the integration of smart technologies into ball valve systems is paving the way for more responsive and automated fluid control solutions. As facilities increasingly leverage data analytics and IoT-driven technologies, the ability to monitor and adjust operations in real-time enhances safety and reliability. As reported in recent market analyses, the demand for technologically advanced ball valves is projected to grow by over 15% annually, indicating a robust shift towards smarter and more adaptable fluid control mechanisms. This trend underscores the critical role that full port ball valves will play in shaping the future of industrial fluid management systems.