Addressing Common Issues with High Pressure Valve Performance

High pressure valves are critical components in numerous industrial applications, yet they often encounter performance issues that can lead to inefficiencies and increased operational costs. According to a report by the International Society of Automation, nearly 30% of valve-related failures in high-pressure systems can be attributed to improper selection and maintenance practices. These failures not only disrupt production processes but can also pose safety risks in environments dealing with hazardous materials.

Understanding the common issues associated with high pressure valve performance is essential for engineers and technicians aiming to enhance reliability and efficiency in their operations. As industries increasingly demand higher performance from their equipment, addressing these challenges becomes imperative, making the exploration of high pressure valve types and their respective operational parameters a crucial topic for ongoing discussion and development.

Understanding High Pressure Valve Fundamentals

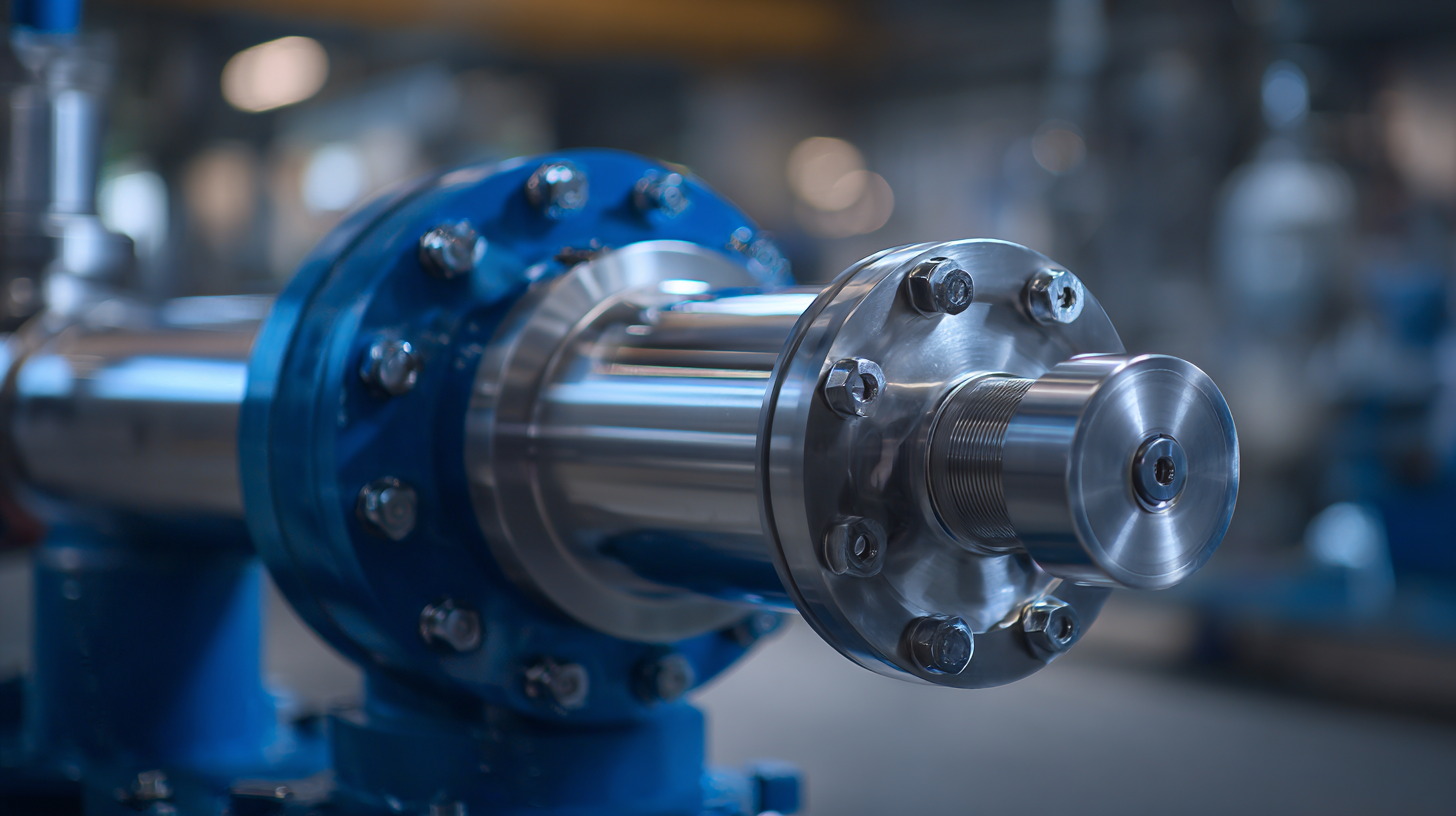

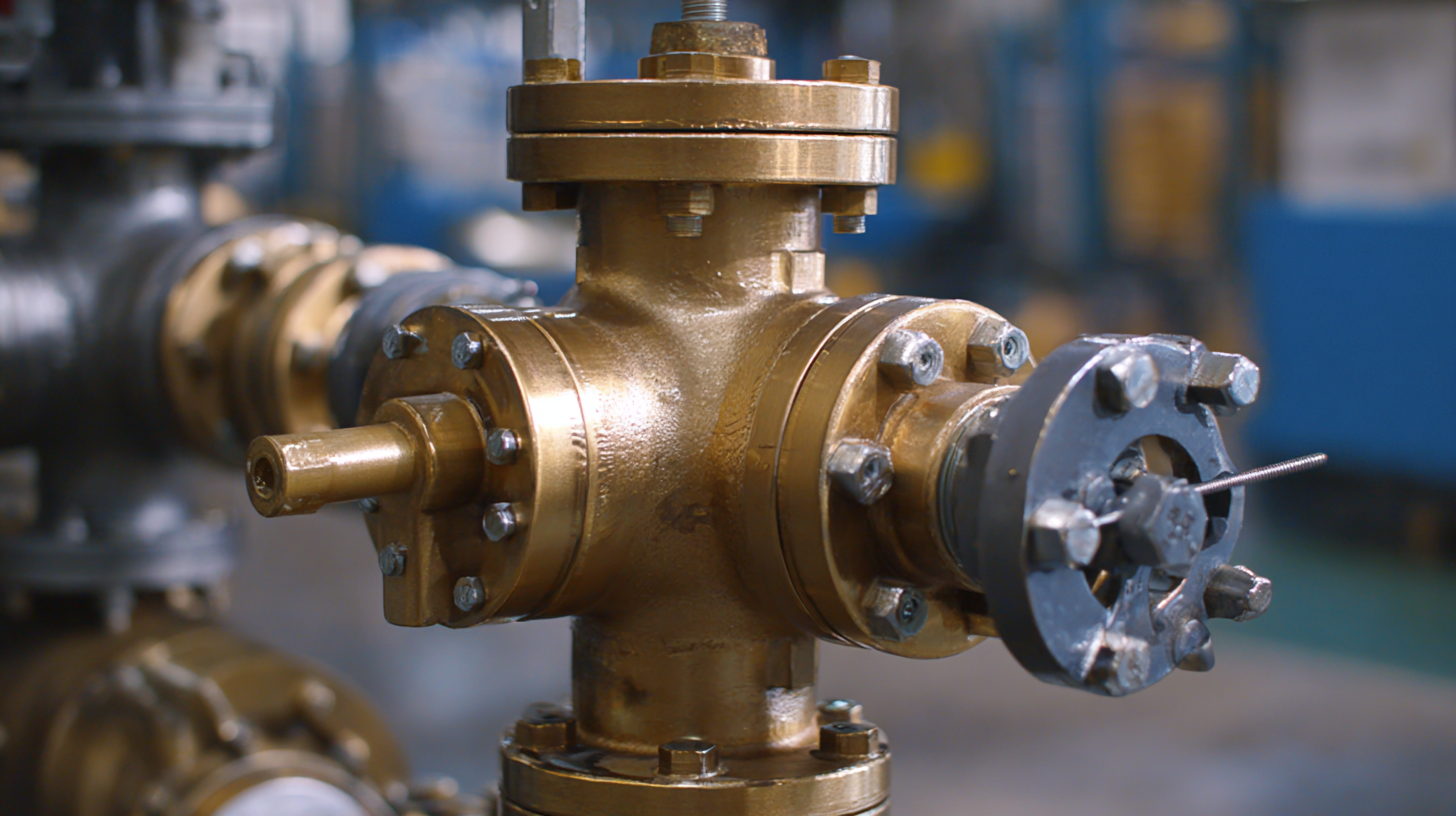

High pressure valves play a crucial role in various industrial applications, ensuring the safe and efficient control of fluid flow under extreme conditions. Understanding their fundamentals is essential for anyone involved in systems where these valves are employed. High pressure valves are designed to withstand intense pressure and temperature fluctuations, making their construction materials and engineering paramount. Typically, they utilize robust materials such as stainless steel or alloyed metals to enhance durability and performance.

High pressure valves play a crucial role in various industrial applications, ensuring the safe and efficient control of fluid flow under extreme conditions. Understanding their fundamentals is essential for anyone involved in systems where these valves are employed. High pressure valves are designed to withstand intense pressure and temperature fluctuations, making their construction materials and engineering paramount. Typically, they utilize robust materials such as stainless steel or alloyed metals to enhance durability and performance.

The operation of high pressure valves is significantly influenced by factors such as design type, sealing mechanisms, and flow characteristics. Ball and gate valves are common choices for high pressure applications due to their ability to provide tight sealing and minimal flow resistance when fully opened. Furthermore, the selection of the appropriate actuator is critical, as it determines the valve's responsiveness and reliability under pressure. With a thorough understanding of these fundamentals, engineers can better address common issues like leakages or valve failures, ultimately ensuring the efficiency and safety of high pressure systems.

Identifying Common Performance Issues in High Pressure Valves

High pressure valves are crucial components in various industrial applications, yet they often encounter performance issues that can compromise system efficiency and safety. Common problems include sticking, leakage, and inadequate sealing, which can arise from factors such as wear and tear, improper installation, or substandard materials. According to a report by the American Society of Mechanical Engineers (ASME), up to 30% of high pressure valve failures can be attributed to these common performance issues, leading to increased downtime and maintenance costs.

To mitigate these challenges, regular maintenance and inspection are essential. Operators should implement a routine check-up schedule, making sure to inspect valve seals and packing for wear. Additionally, using proper lubrication can minimize sticking and prolong the lifespan of the valve.

**Tip:** Consider adopting predictive maintenance techniques that leverage data analytics to foresee potential valve failures before they occur.

Another solution lies in selecting high-quality materials that can withstand extreme pressures and temperatures. Data from the International Society for Automation (ISA) indicates that choosing the right valve material can reduce leak frequencies by up to 50%.

**Tip:** Always consult with manufacturers for suitable valve specifications tailored to your operational conditions, which can significantly enhance performance and reliability.

Addressing Common Issues with High Pressure Valve Performance - Identifying Common Performance Issues in High Pressure Valves

| Issue | Description | Impact on Performance | Possible Solutions |

|---|---|---|---|

| Leakage | Unwanted flow through the valve when it is supposed to be closed. | Can lead to loss of pressure and inefficient operation. | Regular maintenance and seal replacements. |

| Sticking | Valve fails to open or close completely due to mechanical binding. | Causes erratic flow and can damage the valve components. | Lubrication and regular operational checks. |

| Corrosion | Deterioration of valve materials due to chemical reactions with the fluid. | Reduces valve lifespan and can lead to catastrophic failures. | Use of corrosion-resistant materials and regular inspections. |

| Pressure Fatigue | Failure due to repeated exposure to high pressure. | Can cause cracking and complete valve failure. | Introduce pressure relief systems and regular testing. |

| Noise | Unusual sounds during operation indicating turbulence. | Potential sign of inefficiency and can indicate a problem. | Check valve sizing and flow conditions. |

Troubleshooting Techniques for Enhanced Valve Efficiency

In addressing the common issues related to high-pressure valve performance, it’s essential to focus on troubleshooting techniques that can enhance valve efficiency. With advances in imaging technologies such as transesophageal echocardiography, understanding the complexities of heart valves, including the mitral and tricuspid valves, has become paramount. Recent studies illustrate that transcatheter interventions, like the edge-to-edge techniques for tricuspid valve repair, have seen a marked increase in procedural success rates, showcasing the importance of precise imaging in pre-operative assessments.

**Tips:** Regularly monitor the performance metrics of high-pressure valves, specifically focusing on pressure differentials and flow rates. Identifying anomalies early can lead to timely interventions and repairs, ultimately enhancing efficiency.

Moreover, exploring surface modifications for mechanical heart valves has been highlighted as a way to mitigate issues related to wear and tear. This innovative approach not only prolongs valve life but also improves overall hemodynamic performance.

**Tips:** Implement rigorous inspection protocols that include assessing surface integrity and functionality. Advanced imaging techniques can provide invaluable insights, ensuring that any emerging issues are addressed before they escalate.

Preventive Maintenance Practices to Ensure Optimal Valve Function

High pressure valves play a critical role in various industrial applications, yet their performance can be hampered by common issues such as wear, corrosion, and improper maintenance. Implementing preventive maintenance practices is essential to ensure optimal valve function, thereby prolonging the lifespan of these critical components. According to a study by the American Society of Mechanical Engineers, nearly 30% of valve failures are attributed to lack of maintenance, highlighting the importance of regular inspections and timely interventions.

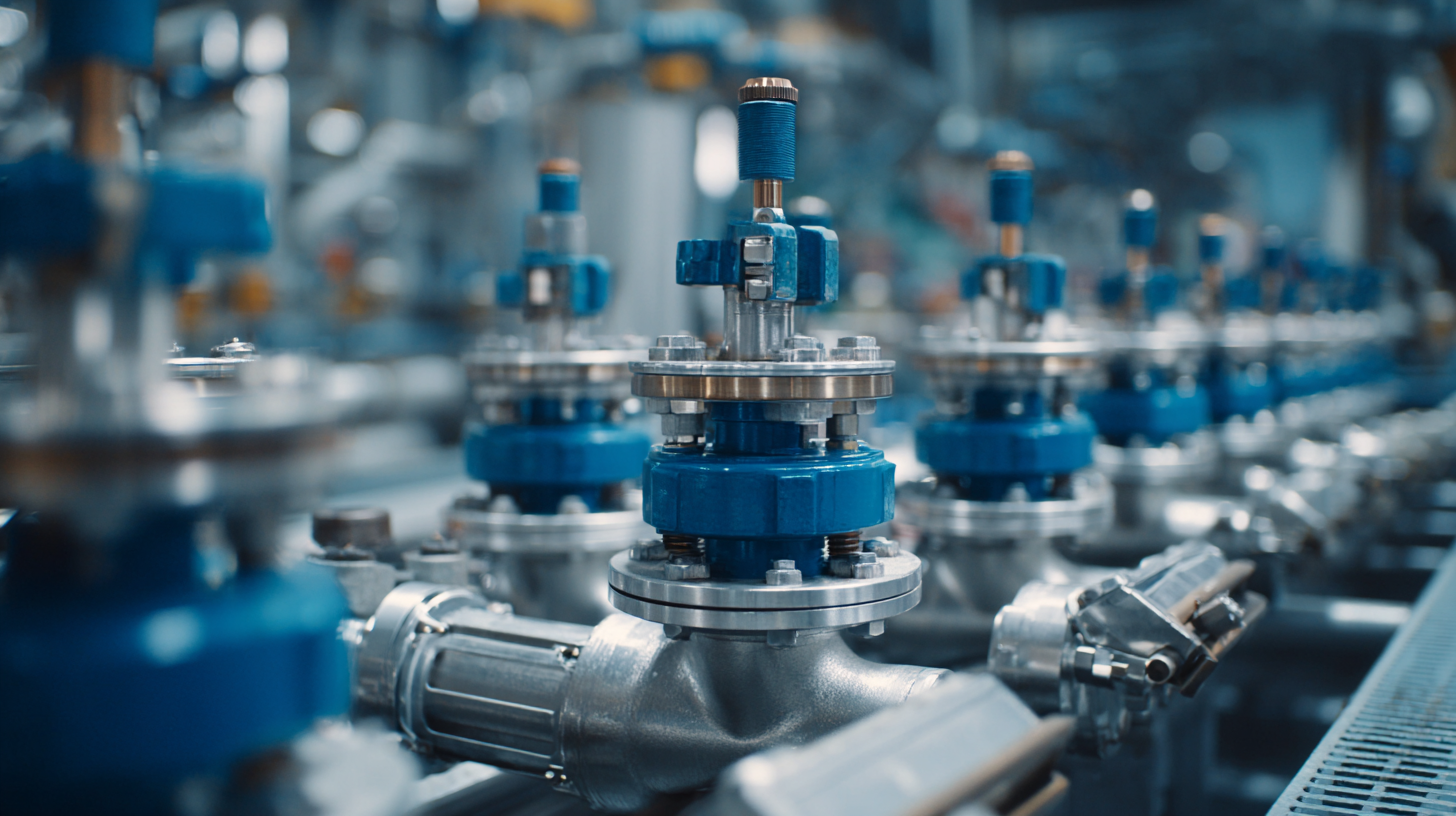

Routine checks should include the inspection of seals and packing, as well as a thorough cleaning process to eliminate debris that could impede valve operation. Additionally, utilizing predictive maintenance techniques can help anticipate potential failures before they occur, thus minimizing downtime and repair costs.

Industry reports suggest that organizations that adopt a proactive maintenance approach can reduce maintenance costs by up to 40% and increase operational efficiency by nearly 25%. By prioritizing preventive maintenance, businesses can optimize the performance of high pressure valves and ensure the integrity of their overall system.

Upgrading Valves: When and How to Enhance Performance

When it comes to enhancing the performance of high-pressure valves, knowing when to upgrade is crucial. Many industries rely heavily on these valves for safety and efficiency in their operations. Over time, wear and tear can lead to decreased reliability, resulting in maintenance issues or even costly downtime. Regular performance evaluations can help identify specific problems such as leaks, inconsistent flow rates, or failure to open or close properly. These indicators often reveal that it’s time to consider an upgrade.

Upgrading valves involves selecting the right materials and technologies that meet modern standards and are suited to the specific application. For instance, replacing older models with advanced designs can improve operational efficiency and safety features, such as better sealing mechanisms and resistance to extreme temperatures. Additionally, integrating smart technology such as IoT sensors can offer real-time performance monitoring, allowing for predictive maintenance and minimizing disruptions. This proactive approach not only enhances the longevity of the valve system but also contributes significantly to overall operational efficiency.