Leading Global Manufacturers of Best Flow Control Valve for International Buyers

In the rapidly evolving landscape of industrial automation, the significance of Flow Control Valves cannot be overstated, as they play a crucial role in regulating the flow of liquids and gases across various sectors. According to a recent market research report by Mordor Intelligence, the global flow control valve market is projected to reach USD 10.67 billion by 2026, growing at a CAGR of around 5.12% from 2021 to 2026. This growth is driven by increasing industrialization, coupled with rising investments in water and wastewater management. As international buyers navigate this competitive landscape, it becomes essential to compare the offerings of leading global manufacturers. This blog will explore the top players in the market, analyzing their technologies, product features, and market positioning to aid buyers in making informed decisions regarding their flow control valve needs.

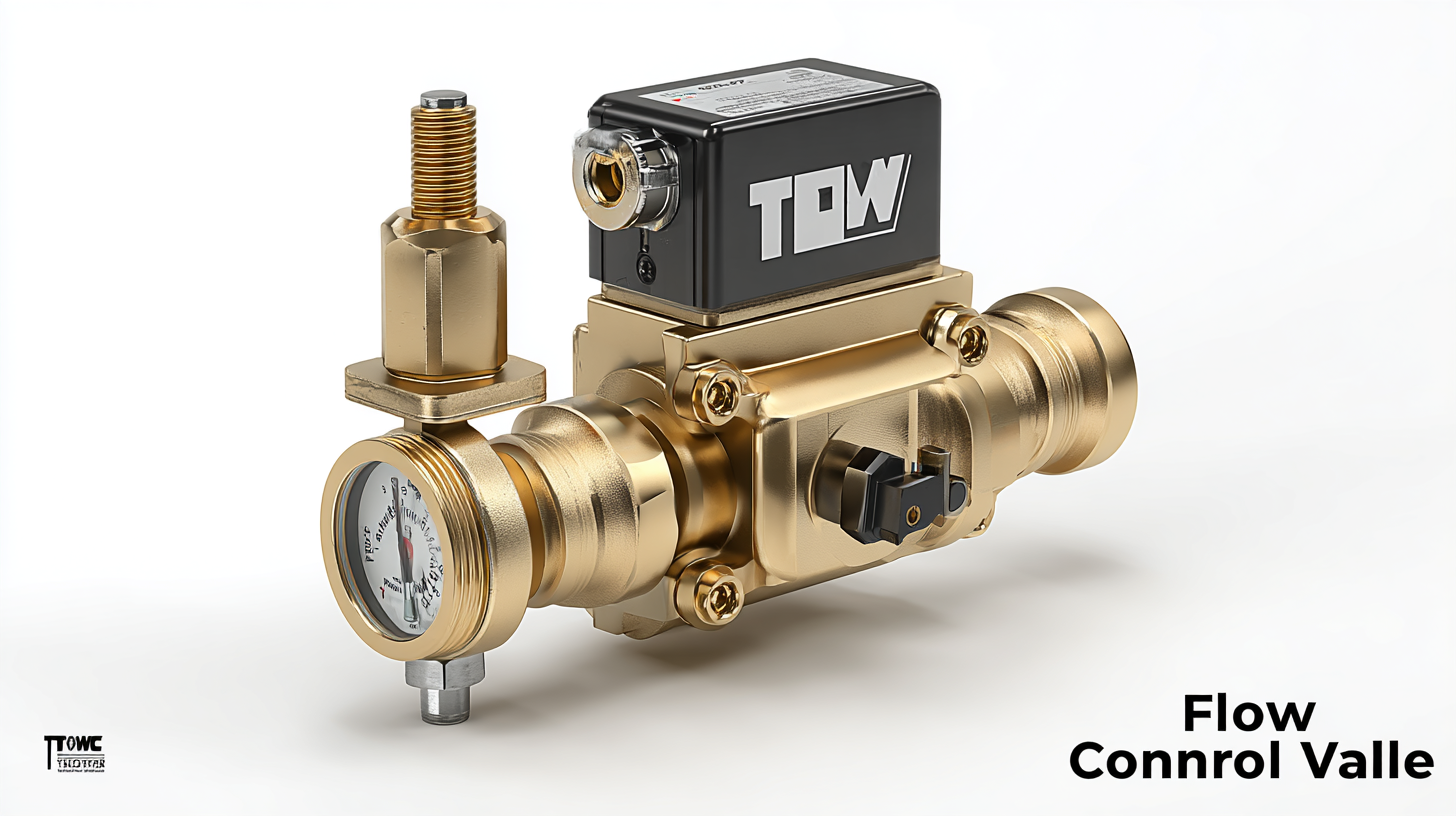

Overview of Flow Control Valves and Their Importance in Manufacturing

Flow control valves are essential components in various industrial processes, playing a critical role in regulating fluid flow, pressure, and temperature. According to a report by Research and Markets, the global flow control valve market is expected to reach USD 10 billion by 2025, driven by the ever-increasing demand from sectors such as oil and gas, water and wastewater treatment, and chemical manufacturing. These valves ensure optimal performance and safety in systems, preventing potential hazards that can arise from improper flow conditions.

In addition to safety and efficiency, flow control valves contribute significantly to energy savings. A study by the International Energy Agency indicated that proper flow control can reduce energy consumption in industrial systems by up to 20%. This highlights their importance not just for operational efficacy but also for environmental sustainability. As industries continue to emphasize green technologies, the demand for advanced flow control valves equipped with smart features and automation will likely rise, influencing the market dynamics in the coming years.

Key Features to Consider When Selecting Flow Control Valves

When selecting flow control valves, several key features should be taken into account to ensure optimal performance and reliability. According to a recent report by Research and Markets, the global flow control valves market is projected to reach approximately $20 billion by 2025, driven by increasing demand in industries such as oil and gas, water treatment, and chemical production. Understanding the specific requirements of your application is crucial, as different valve types—such as globe, ball, and gate valves—offer unique advantages related to flow control efficiency and pressure drop.

Another critical factor to consider is the construction material of the valve. As highlighted in the 2021 Valves Market Analysis by Global Market Insights, valves made from stainless steel and high-performance plastics are favored for their durability and resistance to corrosive environments. Additionally, operators should examine the valve's size and pressure rating, ensuring compatibility with existing piping systems, to avoid costly retrofitting or maintenance downtime. As industries continue to evolve towards automation and precision, evaluating these key features will empower international buyers to make informed decisions when sourcing flow control valves.

Flow Control Valve Market Distribution by Type

Top Global Manufacturers of Flow Control Valves: A Comparative Analysis

The global Eccentric Plug Control Valve market is projected to witness significant growth in the coming years, driven by increased demand across multiple sectors, including water treatment, oil and gas, and chemical processing. With the control valve market projected to reach USD 5,987.50 million, industry players are keenly analyzing their positions and strategizing for future opportunities. A recent comparative analysis of top global manufacturers highlights the importance of innovation and efficiency in capturing market share.

As the diaphragm valve segment also gains traction, with a market size expected to grow from $312.4 million in 2022 to $541 million by 2032 at a CAGR of 5.6%, it is essential for manufacturers to remain agile. Adopting advanced technologies and focusing on sustainable practices can significantly enhance competitive advantages.

Tips for buyers include thoroughly researching valve types that best meet their operational needs by considering factors like pressure ratings and compatibility with various fluids. Additionally, seeking suppliers with robust after-sales support and maintenance services can lead to long-term efficiencies and reliability in valve performance. Emphasizing quality and durability during procurement will help mitigate the risks of operational downtime.

Innovative Technologies in Flow Control Valve Design and Production

The landscape of flow control valve design and production is rapidly evolving, driven by innovative technologies that enhance efficiency and precision across various industries. Recent advancements have highlighted the emphasis on high-purity components, crucial for precision applications, particularly in gas systems. Such developments support industries where contamination control is paramount, showcasing a growing trend toward specialization and advanced manufacturing techniques.

Moreover, a significant area of innovation is in smart control systems, which leverage automation and sophisticated algorithms to improve operational reliability. For instance, the integration of electro-proportional flow control solutions offers enhanced motion control capabilities, ensuring precise adjustments even at high flow rates. This not only enhances performance but also contributes to energy efficiency, addressing the rising demand for sustainable industrial practices.

As these technologies continue to evolve, the flow control valve market is poised for significant transformation, positioning itself as a critical component in modern industrial applications.

Tips for International Buyers: Navigating the Flow Control Valve Market

Navigating the flow control valve market can be challenging for international buyers, especially in a dynamic landscape shaped by geopolitical factors and varying regional needs. Recent discussions between the U.S. and Russia regarding gas flows to Europe underscore the importance of reliable flow control solutions as energy markets remain volatile. This backdrop highlights the necessity for buyers to select reputable manufacturers who can provide advanced valve technologies that ensure operational efficiency.

When sourcing flow control valves, international buyers should consider a few essential tips. First, understand the specific requirements of your applications. Different industries may need valves with distinct performance capabilities, such as pressure ratings and flow characteristics. Secondly, keep an eye on global industry trends and innovations, as demonstrated by recent product launches targeting specific regions, which may offer enhanced control options suited to unique market demands.

Additionally, always prioritize the reputation and reliability of manufacturers. Engaging with companies known for their quality and service can lead to better long-term partnerships and sourcing strategies. By focusing on these aspects, buyers can effectively navigate the complexities of the flow control valve market and make informed purchasing decisions.