How to Leverage the 2025 Technological Trends for Best Flow Valve Innovations

In the rapidly evolving landscape of industrial automation, 2025 heralds a pivotal shift in technological trends that will undeniably influence best practices for Flow Valve innovations. According to a recent study by MarketsandMarkets, the global flow control equipment market is expected to reach USD 34.3 billion by 2025, with a compound annual growth rate (CAGR) of 4.5% from 2020. This anticipated growth underscores the need for manufacturers and engineers to leverage emerging technologies such as IoT, AI, and advanced materials to enhance the efficiency and performance of flow valves. As industries strive for improved process control and energy efficiency, understanding how to harness these technological advancements will be critical for companies aiming to stay competitive in an increasingly complex marketplace.

This blog will explore alternative types of flow valves and how aligning with future trends can lead to groundbreaking innovations.

Strategies for Adapting to 2025's Flow Valve Market Dynamics and Innovations

As we approach 2025, the flow valve market is poised for significant transformation driven by rapid technological advancements and changing consumer demands. To effectively adapt to these dynamics, companies must adopt a proactive strategy that emphasizes innovation and flexibility. Embracing digital technologies such as Internet of Things (IoT) integration and advanced analytics can enhance operational efficiency and improve product reliability. By leveraging data-driven insights, manufacturers can optimize valve performance, predict maintenance needs, and ensure seamless integration into existing systems.

Moreover, sustainability is becoming increasingly crucial in the flow valve industry. Companies need to invest in eco-friendly materials and energy-efficient technologies to meet regulatory requirements and consumer preferences. Innovations in materials science, such as the development of lightweight composites and corrosion-resistant alloys, can lead to enhanced durability and performance. Collaborating with research institutions and technology partners can pave the way for groundbreaking innovations that not only comply with environmental standards but also exceed customer expectations. By focusing on these strategic areas, businesses can position themselves at the forefront of the market by fostering innovation that aligns with 2025's technological trends.

Examining Global Demand: Projected Growth of Flow Valve Technology and Market Reach

The global flow valve technology market is on a promising growth trajectory, with significant expansions expected in various segments. For instance, the HPLC check valve market was valued at $20 million in 2023 and is projected to reach $21.27 million in 2024, ultimately growing to $34.93 million by 2032, reflecting a compound annual growth rate (CAGR) of 6.39%. This trend highlights the increasing demand for efficient and reliable flow control solutions, particularly in the pharmaceutical and chemical industries where precision is paramount.

In the realm of servo valves, the market is anticipated to grow from $4.48 billion in 2023 to $6.5 billion by 2032, indicating a CAGR of approximately 4.22% during the forecast period from 2024 to 2032. This growth is driven by advancements in automation and robotics, which require highly responsive and accurate servo valves. Additionally, the automotive water valve market showcases a similar upward trend, with a projected increase from $109.75 million in 2024 to approximately $128.86 million by 2033, emphasizing the critical role of flow valves in modern vehicle designs that prioritize efficiency and environmental standards.

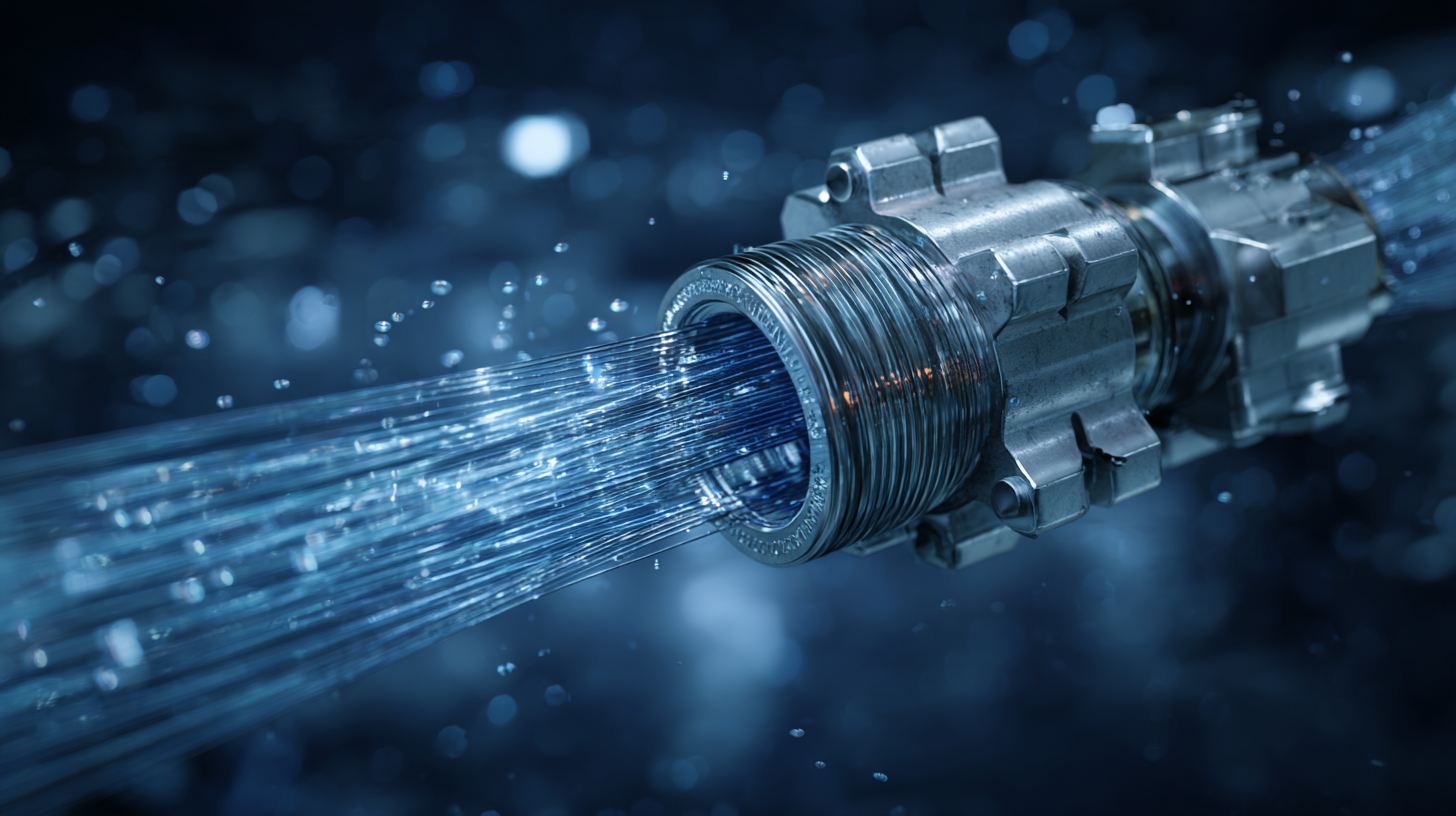

Key Technological Innovations: How IoT and AI Are Transforming Flow Valve Efficiency

The advent of the Internet of Things (IoT) and Artificial Intelligence (AI) is significantly transforming the landscape of flow valve technology. According to a recent report by MarketsandMarkets, the IoT in industrial applications is expected to grow from $155 billion in 2020 to over $400 billion by 2025, indicating a shift towards more interconnected and intelligent systems. This growth is driving innovations in flow valve efficiency, enabling real-time monitoring and predictive maintenance that can drastically reduce downtime.

AI algorithms, when integrated into flow valve operations, enhance performance by analyzing vast amounts of data collected from IoT devices. A study by McKinsey suggests that manufacturing firms implementing AI can increase their productivity by as much as 20%. Advanced data analytics allow companies to optimize valve performance by predicting potential failures before they occur, resulting in cost savings and improved operational efficiencies. The combination of IoT and AI not only streamlines processes but also opens new avenues for innovation, such as self-adjusting valves that respond dynamically to changing conditions, thus maximizing their efficiency in various applications.

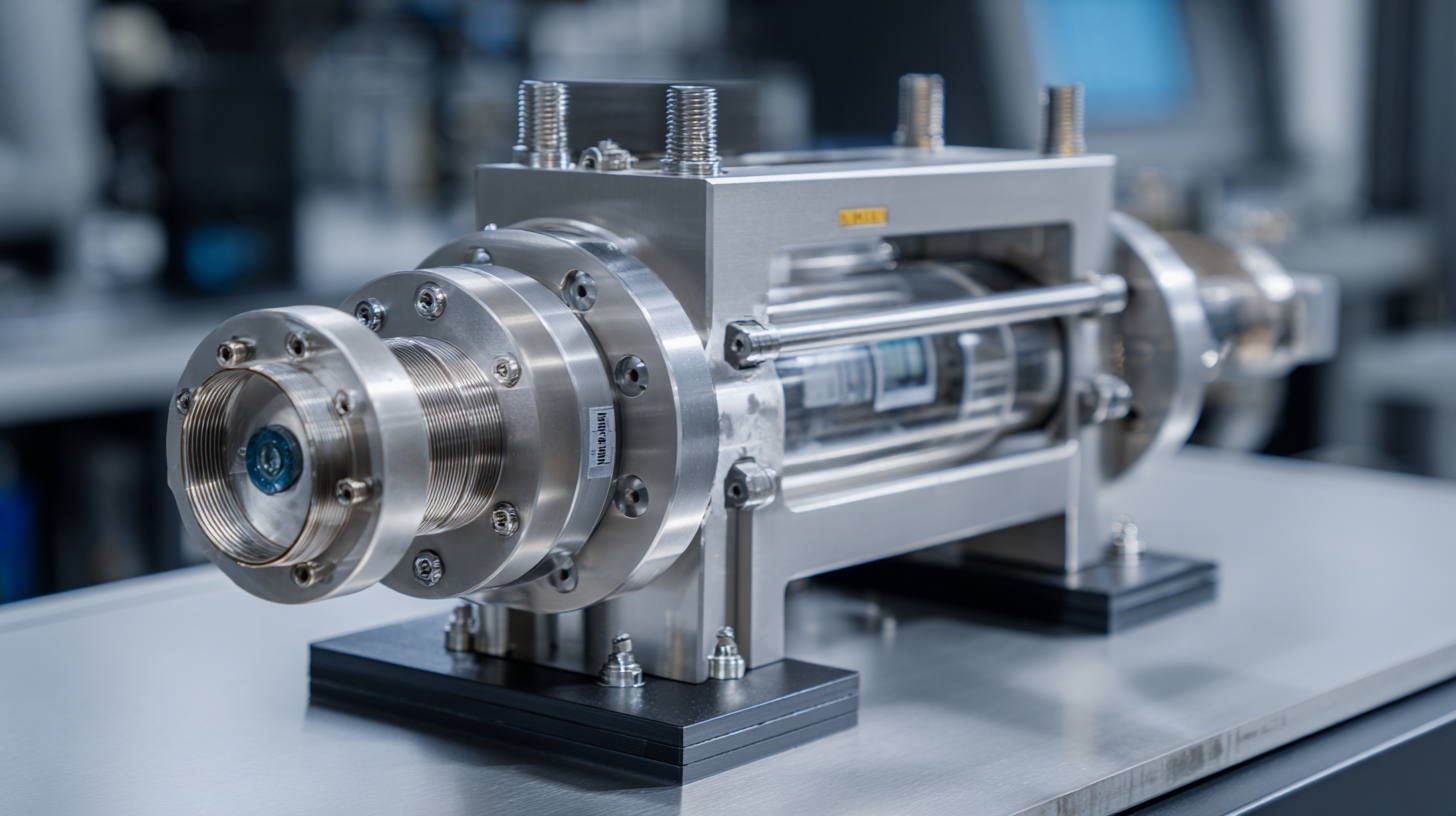

Quality Assurance and Standards: Winning Global Markets through Compliance and Certification

In the ever-evolving landscape of technology, quality assurance and standards play a pivotal role in establishing a competitive edge for flow valve innovations.

As 2025 approaches, manufacturers must prioritize compliance with international standards to gain consumer trust and ensure product reliability. By adhering to rigorous certification processes, companies can not only meet but exceed market expectations, setting a benchmark for quality in the industry.

Investing in quality assurance protocols enhances product performance and durability, crucial factors for industries relying on flow control devices. Utilizing advanced testing technologies and methodologies during the production process allows manufacturers to identify potential issues early, minimizing the risk of costly recalls and repairs. Furthermore, demonstrating commitment to compliance helps in penetrating global markets, where regulatory demands are stringent. By aligning their offerings with international standards, companies can access new business opportunities and foster partnerships that bolster innovation and growth.

Sustainability Trends: Integrating Eco-friendly Practices in Flow Valve Manufacturing

The flow valve manufacturing industry is experiencing a significant shift towards sustainability, driven by increasing regulatory pressures and consumer demand for eco-friendly products. According to a report by MarketsandMarkets, the global green valve market is projected to reach USD 48.9 billion by 2026, growing at a CAGR of 6.9%. This trend is pushing manufacturers to adopt sustainable practices, sourcing materials from recycled or renewable sources and reducing waste throughout the production process.

Integrating eco-friendly practices into flow valve manufacturing not only nurtures the planet but also enhances operational efficiency. A study by McKinsey indicates that companies focusing on sustainability can achieve a 70% reduction in carbon emissions and a 30% decrease in operational costs over five years. Manufacturers are innovating by developing valves that are not only energy-efficient but also made from environmentally responsible materials, ensuring compliance with emerging environmental standards. By leveraging sustainable trends, manufacturing firms can capitalize on new markets while contributing to a greener future.

How to Leverage the 2025 Technological Trends for Best Flow Valve Innovations - Sustainability Trends: Integrating Eco-friendly Practices in Flow Valve Manufacturing

| Trend Category | Description | Impact on Flow Valve | Eco-friendly Practices | Expected Outcome |

|---|---|---|---|---|

| Automation | Implementation of smart technologies for valve operation | Increased efficiency and reduced human error | Minimize energy consumption through optimized operations | Improved operational reliability |

| Sustainability | Shift towards eco-friendly materials in manufacturing | Reduction in carbon footprint of production | Use of recyclable and biodegradable materials | Enhanced brand reputation |

| Digital Integration | Integration of IoT for real-time monitoring | Better maintenance and fault detection | Remote control and diagnostics | Increased system longevity |

| Resource Efficiency | Innovative designs that use less material | Cost savings in manufacturing | Adoption of lean manufacturing practices | Lower production costs |

| Regulatory Compliance | Adherence to environmental regulations | Reduction of legal risks | Continuous assessment and reporting | Improved market access |