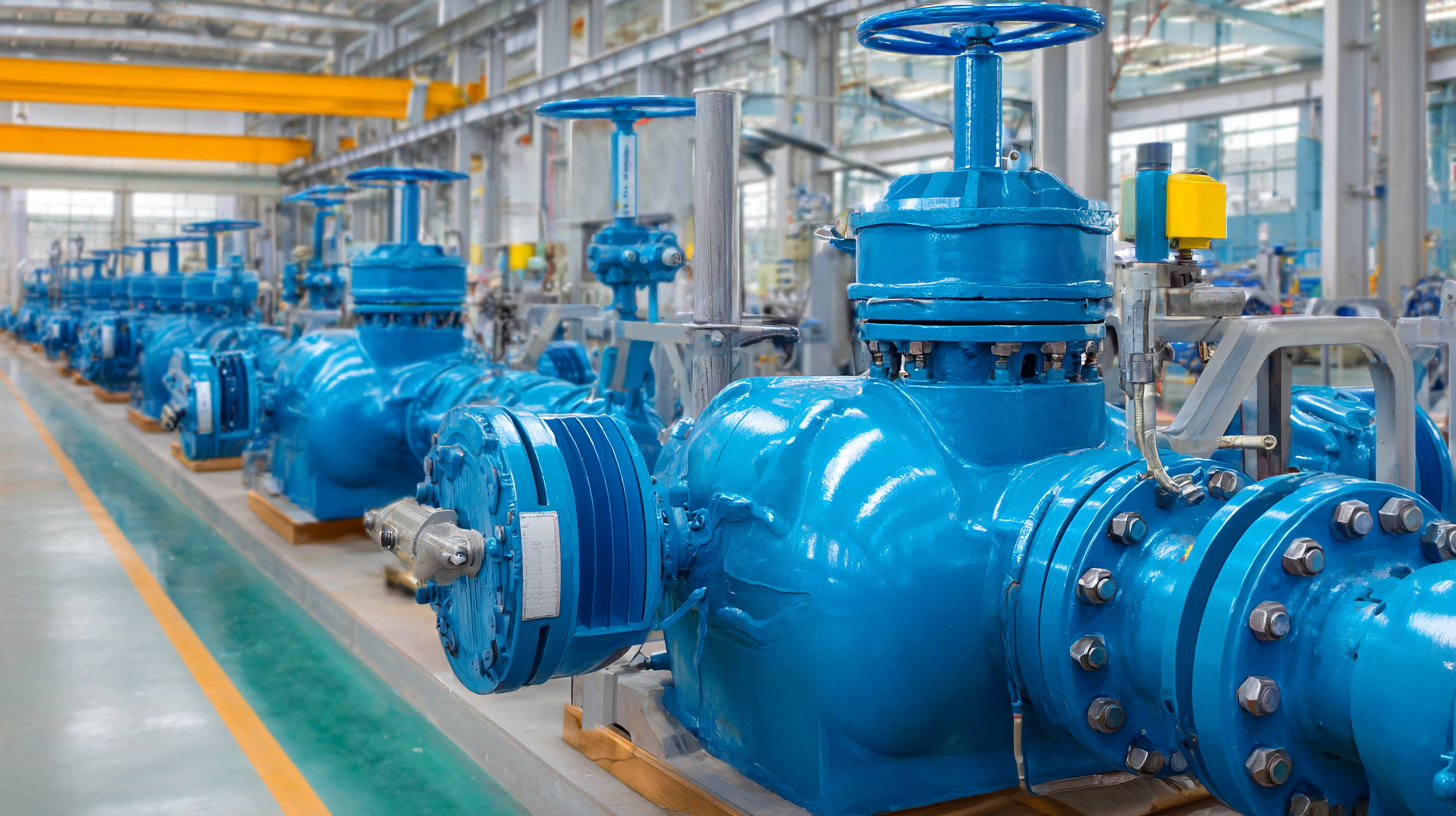

Maximizing Investment: The Benefits of After-Sales Service for Best Ball Valve Control Valve Maintenance

In the realm of industrial automation, the significance of Ball Valve Control Valve maintenance cannot be overstated. According to a report by MarketsandMarkets, the global control valve market is projected to reach $10 billion by 2025, highlighting the increasing reliance on these critical components for operational efficiency. Proper after-sales service not only prolongs the lifespan of ball valves but also ensures optimal performance, reducing downtime and maintenance costs. A lack of proper maintenance can lead to significant financial losses; an estimated 30% of companies experience unplanned downtime due to equipment failures, as reported by the Aberdeen Group. This underscores the importance of integrating robust after-sales support in investment strategies for ball valve control systems, ensuring that businesses can maximize their return on investment while enhancing reliability and productivity.

Importance of After-Sales Service in Ball Valve Maintenance

After-sales service plays a crucial role in maintaining the optimal performance of ball valves, especially in control applications. This component of customer support ensures that any potential issues are addressed promptly, significantly reducing downtime and maintaining operational efficiency. By providing regular maintenance checks, troubleshooting assistance, and replacement parts, after-sales service not only enhances the longevity of the valves but also boosts the confidence of users in the reliability of their systems.

Moreover, effective after-sales service helps customers to better understand their equipment, empowering them to implement best practices in valve maintenance. Comprehensive training provided by service teams equips personnel with the skills necessary to recognize signs of wear or malfunction early on. This proactive approach minimizes unexpected failures, which can lead to costly repairs and production losses. Consequently, investing in after-sales service is not just about immediate support; it is a strategic move that contributes to long-term operational success and financial savings.

Key Features of Effective After-Sales Support for Control Valves

Effective after-sales support is crucial for maintaining the performance and longevity of control valves, particularly ball valves. One of the key features of efficient after-sales service is the provision of regular maintenance checks. These scheduled assessments allow for early detection of potential issues, ensuring that the control valves operate at their optimal efficiency. Additionally, comprehensive training for facility staff can vastly improve their understanding of valve operation and maintenance, leading to better overall management and reduced downtimes.

Another essential aspect of after-sales support is the availability of spare parts and technical assistance. Quick access to replacement parts minimizes equipment downtime, which is vital for maintaining productivity in industrial settings. Moreover, a responsive technical support team can address concerns or troubleshooting needs promptly, reducing uncertainty and keeping operations running smoothly. By prioritizing these features in after-sales service, companies can not only maximize their investment in control valves but also enhance their operational resilience and efficiency.

Best Practices for Implementing After-Sales Maintenance Strategies

Implementing effective after-sales maintenance strategies is crucial for the longevity and efficiency of best ball valves and control valves. One best practice is to establish a regular maintenance schedule, which ensures that valves operate smoothly and prevents unexpected failures. By following a systematic approach, businesses can predict maintenance needs, reducing downtime and extending the lifespan of their equipment.

Training staff is another vital aspect of successful after-sales service. Personnel should be equipped with the knowledge and skills to perform routine checks and minor repairs. This not only empowers employees but also helps in identifying potential issues before they escalate into significant problems.

Furthermore, leveraging data analytics can enhance maintenance strategies by providing insights into performance patterns, enabling proactive rather than reactive service interventions. By integrating these best practices, companies can maximize their investment in ball valves and control valves, resulting in improved operational efficiency and reduced costs.

Measuring the ROI of After-Sales Services in Valve Performance

After-sales service plays a pivotal role in maximizing investment returns, particularly in the maintenance of ball valves and control valves. By ensuring that these components operate at peak performance, companies can significantly enhance the lifespan and efficiency of their systems. Research indicates that effective after-sales services can lead to a 20-30% improvement in equipment reliability, directly correlating to ROI in performance metrics. Given that the global automotive test equipment market is projected to grow from USD 4.1 billion in 2024 to USD 6.4 billion by 2034, industries must recognize and harness after-sales service as a strategic advantage.

Tips for improving ROI through after-sales service include regularly scheduled maintenance checks to address potential issues before they lead to costly downtimes. Stakeholders ought to invest in training staff on best practices for valve operation and maintenance, as knowledgeable personnel can optimize system performance. Furthermore, establishing a robust feedback loop can yield invaluable insights from technicians, enhancing the overall service quality and prolonging the life of valves.

Incorporating advanced service features, such as real-time monitoring and predictive maintenance, can also serve to optimize valve performance. By analyzing service data, organizations can tailor their maintenance strategies, resulting in reduced operating costs and increased efficiency. Investing in after-sales services not only protects investments but also drives innovation within the industry, ultimately positioning companies for sustained growth in a competitive market.

Customer Feedback: Enhancing After-Sales Services for Optimal Results

Customer feedback is a vital component in enhancing after-sales services, particularly for complex equipment like ball valves and control valves. Gathering insights directly from users provides manufacturers and service providers with invaluable knowledge about the performance and reliability of their products post-purchase. This information can drive improvements in after-sales service, ensuring that maintenance protocols are not only effective but also tailored to meet the specific needs of end-users. By actively soliciting customer feedback through surveys or direct communication, companies can identify common issues and areas for enhancement, leading to more efficient maintenance strategies.

Moreover, leveraging customer feedback can foster a stronger relationship between manufacturers and their clients. When customers see their suggestions being incorporated into service upgrades, it builds trust and loyalty, ultimately leading to a more satisfactory experience. Enhanced after-sales services, informed by user experiences, can also minimize downtime and extend the lifespan of equipment, maximizing the overall investment. This collaborative approach ensures that both the supplier and the customer benefit, creating a winning scenario in the highly competitive industrial market.

Customer Feedback on After-Sales Service for Control Valve Maintenance

This chart illustrates the feedback from customers regarding the after-sales services received for control valve maintenance. The data showcases the percentage of customers rating various aspects of the service, highlighting key areas for improvement and overall satisfaction.