How to Optimize Efficiency with Control Valve Balls in Industrial Applications

In industrial applications, maximizing efficiency is critical for maintaining competitive advantage and reducing operational costs. One key component that significantly impacts performance is the Control Valve Ball. According to a report by the International Society of Automation, optimizing control valves can lead to efficiency improvements of up to 20% in fluid handling processes. As industries increasingly prioritize sustainability and cost-effectiveness, understanding the intricate workings of Control Valve Balls becomes essential.

These components not only regulate flow but also influence energy consumption and emissions, making their optimization a focal point for engineers and managers alike. By harnessing advanced materials and innovative designs, businesses can enhance the responsiveness and durability of their Control Valve Balls, thus achieving superior control and efficiency in their operations.

Understanding the Importance of Control Valve Balls in Industrial Processes

Control valve balls play a critical role in optimizing industrial processes by ensuring precise flow control and enhancing efficiency. According to a recent report by Market Research Future, the global industrial valve market is projected to reach $105 billion by 2027, with substantial growth driven by increasing demand for effective flow control solutions. Control valve balls, particularly those made from advanced materials like stainless steel and engineered plastics, offer superior durability and resistance to corrosion, making them essential in sectors such as oil and gas, chemical processing, and water treatment.

The importance of control valve balls extends beyond mere functionality; they are pivotal in minimizing energy consumption and reducing operational costs. According to a study by the American Society of Mechanical Engineers (ASME), improper valve selection can lead to energy losses exceeding 20% in some systems. By investing in high-quality control valve balls that provide better sealing and flow characteristics, industries can achieve more consistent performance, ultimately leading to significant cost savings. Enhanced flow control not only improves system efficiency but also contributes to a more sustainable operational footprint by reducing waste and energy expenditure.

Selecting the Right Material for Control Valve Balls to Enhance Performance

Selecting the right material for control valve balls is crucial for enhancing performance in industrial applications. Control valve balls are commonly made from a variety of materials, including stainless steel, brass, and polymers. According to a report by the Flow Control Corporation, the correct choice of material can reduce wear and corrosion significantly, which is essential in environments where fluids may contain abrasive particles or corrosive chemicals. For instance, stainless steel balls provide superior strength and corrosion resistance, making them ideal for applications involving aggressive media, while polymer materials offer excellent chemical resistance and lower friction in softer applications.

Additionally, the material selection influences the temperature and pressure ratings of the control valve system. In high-temperature applications, such as oil and gas processing, materials like high-performance alloys or special-grade stainless steels are preferred. Research indicates that using the appropriate alloy can extend the lifespan of valve components by up to 40%, dramatically reducing maintenance costs and downtime. Thus, understanding the specific requirements of an application—including environmental factors, fluid characteristics, and operational demands—is essential for optimizing the efficiency of control valve systems in industrial settings.

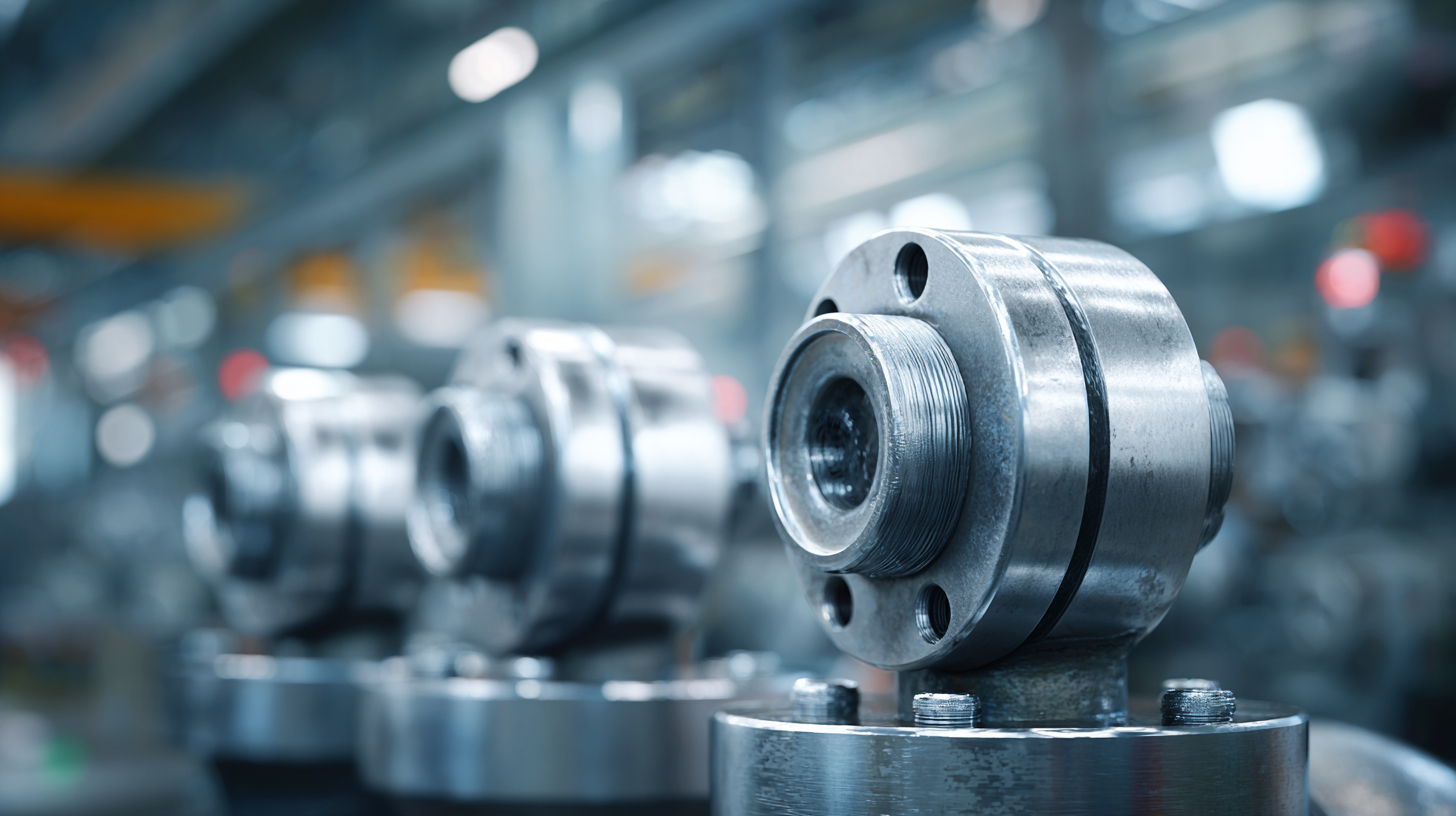

Techniques to Minimize Wear and Tear on Control Valve Balls

In industrial applications, control valve balls play a crucial role in regulating flow and ensuring system efficiency. However, these components are subjected to significant wear and tear over time, which can lead to increased maintenance costs and reduced operational efficiency. To minimize this wear, several techniques can be employed.

One effective approach is to select materials with high abrasion resistance for the valve balls. Using ceramic or specially treated metals can greatly enhance durability and extend the lifespan of the components. Additionally, optimizing the flow rate and pressure conditions can prevent excessive friction and wear. Regular inspection and maintenance routines are also essential; implementing predictive maintenance strategies can help identify potential issues before they escalate.

**Tips:**

- When replacing valve balls, choose products specifically designed for the media being handled to ensure compatibility and performance.

- Implement flow control strategies to keep velocities within optimal ranges and reduce turbulent flow, which can contribute to wear.

- Consider using lubricants where applicable to create a smoother operational environment and minimize contact wear between moving components.

Control Valve Ball Wear Analysis in Industrial Applications

Strategies for Regular Maintenance and Inspection of Control Valve Components

Regular maintenance and inspection of control valve components are crucial for ensuring optimal performance in industrial applications. Control valve balls, as key components, require systematic checks to prevent inefficiencies, leaks, or failures. Establishing a routine maintenance schedule helps in identifying wear and tear early, minimizing unplanned downtime and costly repairs. It is essential to inspect the valve balls for signs of corrosion, pitting, or erosion, which can severely impact their functionality.

In addition to visual inspections, utilizing advanced diagnostic tools can enhance the efficiency of maintenance practices. Pressure tests and leak detection methods should be incorporated to assess the tightness and functionality of control valves. Moreover, keeping an inventory of spare parts allows for quick replacements during scheduled maintenance, thus reducing the impact on operations. By implementing these strategies, industries can ensure that their control valve systems remain in peak condition, ultimately optimizing efficiency and reliability in manufacturing processes.

Implementing Automation for Improved Control Valve Ball Efficiency

In today’s industrial landscape, optimizing control valve ball efficiency is crucial for enhancing operational performance. Implementing automation is a key strategy that many organizations are adopting to streamline processes and reduce downtime. According to a report by the International Society of Automation, automating valve controls can improve operational response time by up to 15%, leading to significant productivity gains. This enhanced efficiency is primarily due to the reduction of manual errors and the ability to monitor operations in real-time.

Furthermore, integrating advanced technologies such as AI and IoT with control valve balls allows for predictive maintenance, which can minimize unplanned outages. A study by the McKinsey Global Institute indicates that predictive maintenance can reduce maintenance costs by 30% to 40%. By utilizing automated systems, industries can not only achieve better control over fluid dynamics but also significantly extend the lifespan of valve components. This strategic shift towards automation not only bolsters efficiency but also aligns with the growing demand for sustainable practices in industrial applications.

Related Posts

-

Innovative Solutions for Enhancing Efficiency in Valve Control Valve Applications

-

Maximizing Investment: The Benefits of After-Sales Service for Best Ball Valve Control Valve Maintenance

-

7 Essential Tips for Selecting Top Manufacturers of Best Automation Valves in 2024

-

Challenges Faced by Global Buyers When Sourcing Flanged Ball Valves

-

Solutions for Optimizing Fluid Dynamics with the Best Flow Valve in Global Industries

-

How to Choose the Right High Temperature Ball Valve for Your Industry Needs