Solutions for Optimizing Fluid Dynamics with the Best Flow Valve in Global Industries

In the ever-evolving landscape of global industries, optimizing fluid dynamics is paramount for enhancing operational efficiency and reducing costs. Flow valves, critical components in various systems, play a pivotal role in managing the flow of liquids and gases, thereby influencing performance and reliability. According to a recent report from MarketsandMarkets, the global flow valve market is projected to reach USD 20.7 billion by 2025, growing at a CAGR of 6.1% from 2020. Despite the advancements, many industries face challenges such as pressure drops and inefficient flow regulation, which can lead to significant operational disruptions. Therefore, addressing these issues with the best flow valve solutions is not merely a technical necessity but a strategic imperative for maintaining industry standards and competitiveness in today's market.

Understanding Fluid Dynamics: Key Principles and Applications

Fluid dynamics plays a critical role in various industrial applications, influencing processes like filtration, mixing, and energy efficiency. Understanding the key principles of fluid dynamics, such as laminar and turbulent flow, viscosity, and pressure differentials, is essential for optimizing systems like hollow fiber nanofiltration membrane modules. Recent computational fluid dynamics (CFD) studies have shown that flow patterns in these modules directly affect separation performance and energy consumption. A comprehensive analysis demonstrated that optimizing the fluid flow conditions can lead to improvements in operational efficiency of up to 30%, highlighting the significant impact of fluid dynamics in industrial applications.

Moreover, advancements in technology, including the use of Large Language Models (LLM) like Llama 3, are paving the way for new predictive capabilities in fluid dynamics. By leveraging machine learning to forecast fluid behavior, industries can simulate various scenarios more accurately, reducing the time and cost associated with traditional trial-and-error methods. Techniques like piezoelectric inkjet printing further illustrate the challenges inherent in managing fluid flow, where precise delivery and control can enhance product quality and production efficiency. As industries continue to innovate, the integration of these advanced methodologies will undoubtedly refine the understanding and application of fluid dynamics across the globe.

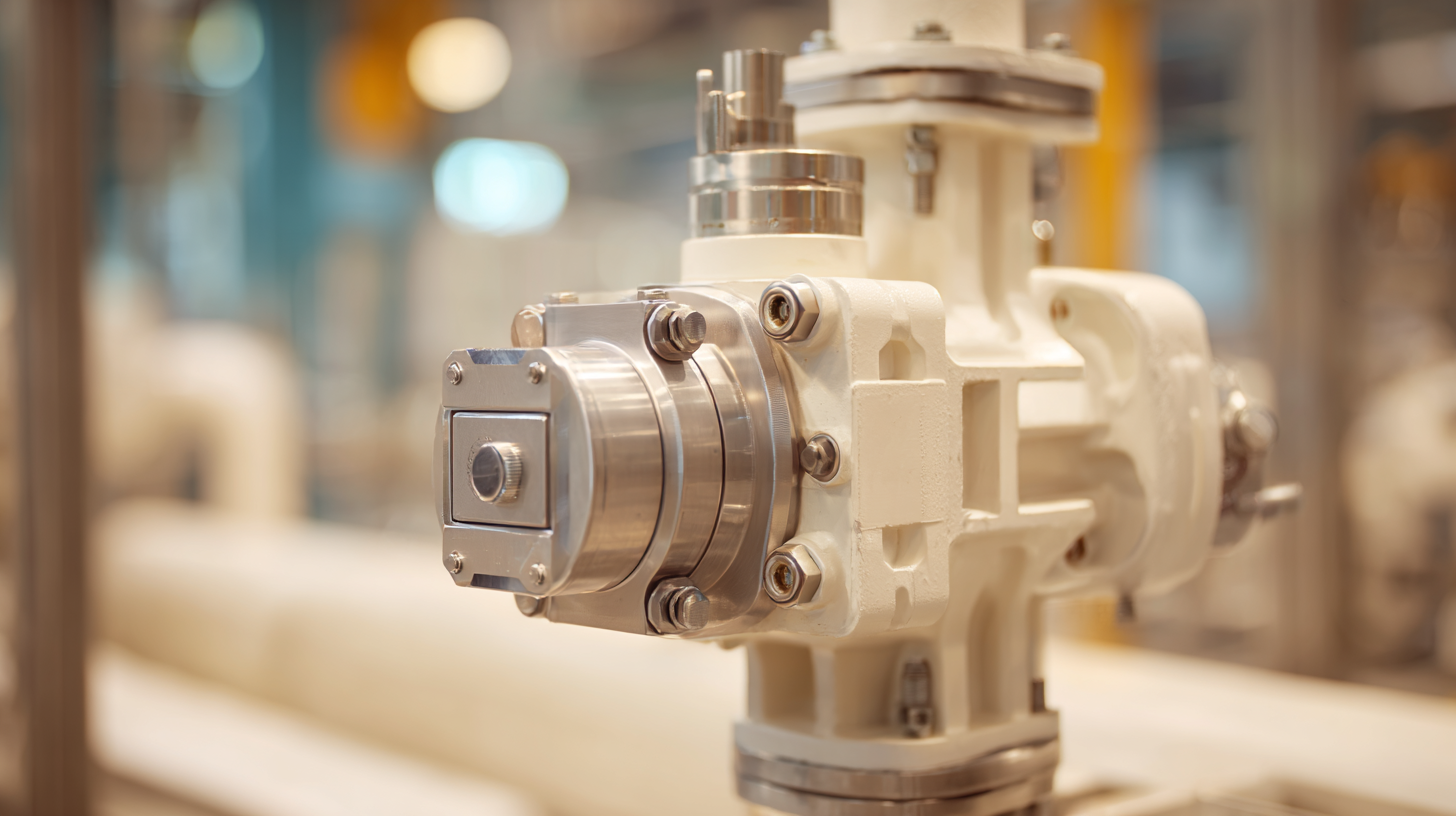

Choosing the Right Flow Valve: Factors to Consider for Optimal Performance

When selecting the right flow valve for optimizing fluid dynamics in various industries, several key factors must be considered to ensure optimal performance. One of the most crucial elements is the valve type, which can significantly affect flow characteristics. For instance, globe valves are excellent for throttling applications, while ball valves offer better sealing capabilities and are ideally suited for on-off control. Understanding the specific application requirements will help determine the most suitable valve type for your system.

Another important factor is the material of the valve. Depending on the fluid being transported, it's vital to choose materials that can withstand the fluid's corrosiveness and temperature. For aggressive chemicals, materials like stainless steel or corrosion-resistant alloys may be necessary, while PVC might suffice for less harsh environments. Additionally, pressure ratings and flow capacity should be examined to ensure that the valve can handle the system’s demands without compromising safety or efficiency. By carefully evaluating these aspects, industries can achieve better control over their fluid dynamics and enhance overall system performance.

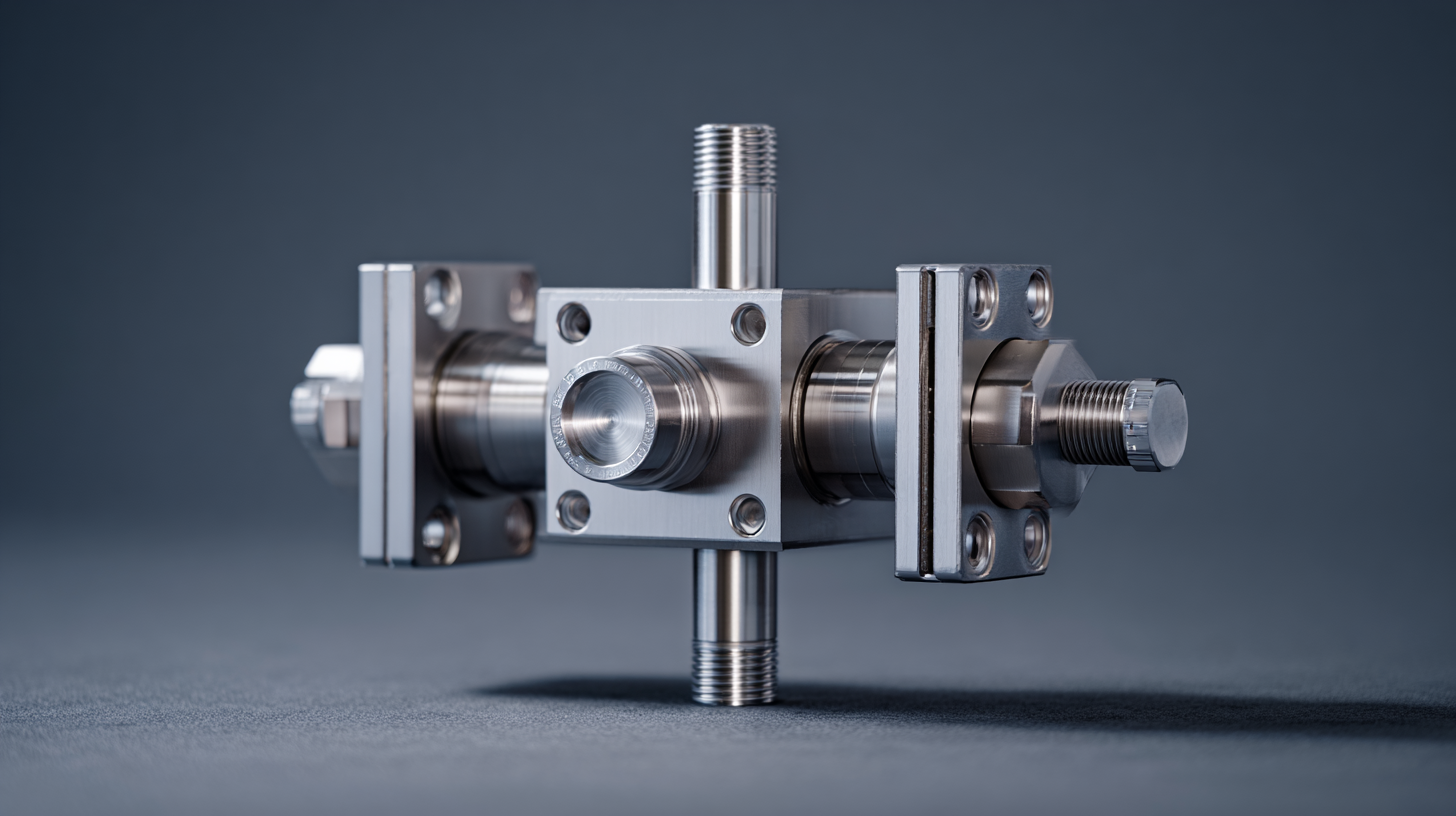

Top Technologies in Flow Valves: Innovations Driving Efficiency

In today's rapidly evolving industrial landscape, the optimization of fluid dynamics is critical for enhancing operational efficiency. Key innovations in flow valve technologies are leading the charge, with the integration of AI-powered operational intelligence changing the game. These advanced systems offer predictive analytics, allowing industries to foresee potential issues and streamline maintenance processes, ultimately saving both time and resources.

Sustainable water treatment practices are also becoming more prevalent, showcasing a commitment to environmental stewardship. Industries are now investing in decentralized infrastructure solutions that not only reduce water wastage but also bolster flood prevention efforts. Tips for companies looking to implement these technologies include conducting thorough assessments of existing systems to identify inefficiencies and prioritizing investments in smart technologies that adapt to specific operational needs.

Furthermore, the recent funding rounds for companies focused on valve technology signify a robust trend towards innovating within this space. For those involved in the water and energy sectors, keeping abreast of the latest advancements is crucial. Sharing best practices and collaborating on technology deployment can foster a more sustainable approach to fluid management across global industries.

Common Challenges in Flow Dynamics and How to Overcome Them

Fluid dynamics is an essential aspect of various industries, but it comes with its own set of challenges. One common issue is inefficient flow rates, which can lead to unnecessary energy consumption. According to a report by the U.S. Department of Energy, optimizing process fluids can enhance efficiency by up to 30%, demonstrating the importance of using the correct flow valves. Selecting valves that minimize turbulence and ensure smooth transitions can make a significant difference in system performance.

Another challenge faced by industries is pressure drop resulting from inadequate valve selection and design. A recent study from the International Journal of Engineering Research highlights that improper flow valve configurations can induce a pressure drop of up to 25%, impacting overall system efficiency. Employing advanced flow valves designed to reduce such losses can address this issue, ensuring that fluid delivery systems operate within optimal parameters while maintaining energy efficiency and cost-effectiveness. By tackling these challenges head-on with the right technologies and practices, industries can achieve significant improvements in fluid dynamics.

Optimizing Fluid Dynamics: Common Challenges and Solutions

Maintenance Tips for Enhancing Flow Valve Longevity and Performance

Maintaining the longevity and performance of flow valves is crucial in optimizing fluid dynamics across various global industries. According to a report by Grand View Research, the global industrial valves market is expected to reach USD 100 billion by 2025, highlighting the importance of reliable flow control mechanisms. Regular maintenance can significantly prolong the life of these valves and improve efficiency. Key practices include routine inspections and cleaning, which can help identify wear and tear early on. Failure to maintain valves can lead to costly downtime; studies show that unplanned maintenance can cost industries up to 20% more than planned maintenance initiatives.

Incorporating predictive maintenance strategies can further enhance flow valve performance. A report from ResearchAndMarkets indicates that predictive maintenance can decrease costs by up to 30% while extending equipment lifespan by up to 50%. Utilizing advanced monitoring technologies can provide real-time data on valve performance, allowing for timely interventions that prevent catastrophic failures. Furthermore, ensuring that valves are operated within their specified parameters, as noted by the American Society of Mechanical Engineers (ASME), can prevent excessive wear and maintain optimal performance levels. Adopting these maintenance practices is crucial in achieving operational efficiency and reducing overall costs in fluid dynamic systems.